The art of lipstick, perfected in silicone: how Citus Kalix set a beauty industry standard

In the silent choreography of a beauty routine, few gestures are as iconic as the swipe of a lipstick. It’s simple, precise, and instantly expressive. Behind that perfect bullet lies a process grounded in innovation, materials science, and industrial expertise.

At the center of this process is Citus Kalix, the French company that, in 1996, filed the original patent for silicone lipstick molding technology. Since then, this innovation has become a defining standard in the cosmetics industry. Today, more than 160 Citus Kalix machines are running worldwide, and several leading luxury brands are entirely equipped with Citus solutions, from mold to machine.

A decisive innovation that redefined manufacturing standards

Before the introduction of silicone, lipstick molds were made of metal, which limited precision and made demolding more complex. Citus Kalix introduced silicone as a molding material to overcome these issues. Its elasticity and stability allowed for clean, repeatable demolding without distortion, while maintaining even the most intricate details of the lipstick bullet.

This improvement didn’t just raise production quality. It opened the door to creative possibilities that were previously unfeasible on an industrial scale. Within a few years, the technology was adopted by high-end manufacturers seeking sharper finishes, greater consistency, and new design freedom. Since the patent in 1996, this solution has remained a reference for excellence.

Made in France, trusted worldwide

Every mold is produced in Citus Kalix’s facility in France. This ensures total control over the production process, from raw material formulation to final inspection. The commitment to traceability and quality allows the company to meet the strictest standards required by global cosmetic brands.

Over the last 20 years, Citus Kalix has supplied several million molds to manufacturers in more than 20 countries worldwide, including China, Japan, North America, Canada, Mexico, Brazil, Colombia, Argentina, North Africa, Bangladesh, Greece, Poland, Italy, Spain, and France.

In 2024 alone, production reached nearly 1 million units, supported by a specialized team of 4 project managers and 7 production specialists. Each mold reflects an ongoing process of technical refinement: enhanced silicone compounds, improved mechanical resistance, and evolving customization options. The result is a product that guarantees consistency over time, even under demanding production conditions.

But molds are only one part of the solution. The company offers dedicated customer support, from technical assistance to co-engineering services, ensuring that each client receives tools tailored to their needs.

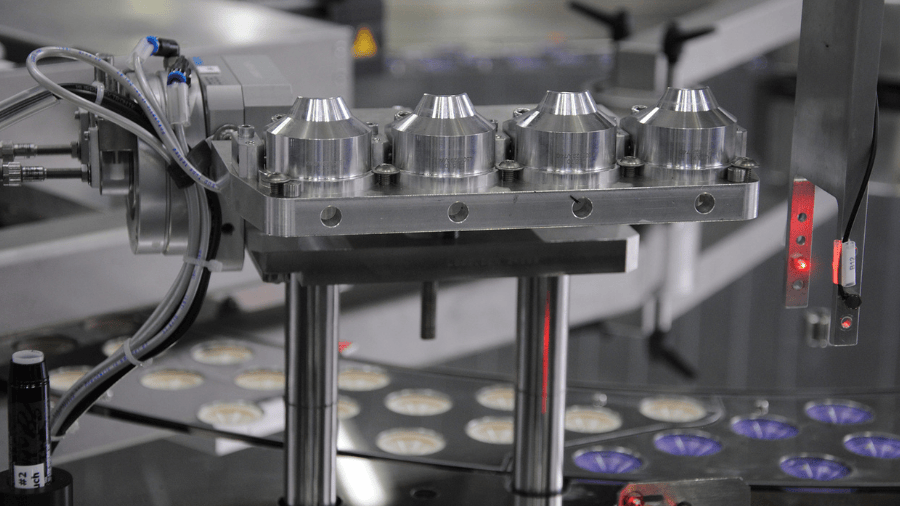

Precision machines, built for performance

The Citus Kalix machine range is designed to cover every production scale, combining robust construction with intuitive interfaces and fast changeovers. Whether for small-scale runs or industrial volumes, each model prioritizes reliability and careful product handling.

The CRLA10 offers a compact footprint, producing up to ten lipsticks per minute. Manual mold loading on a rotary table makes it ideal for limited spaces or lab-scale production. Integrated systems such as a 10L kettle and chiller ensure precise temperature control, while the touchscreen simplifies setup and operation.

For higher output, the CRLA20 MF doubles production speed to twenty lipsticks per minute and integrates four picking stations. The kettle is positioned on a forklift, allowing direct connection to the machine and faster material transfer with minimal handling.

At the top of the range, the CRLA60 MF delivers up to sixty lipsticks per minute, with 384 molds in operation and a fully integrated kettle. Designed for continuous production, this model minimizes downtime and maximizes repeatability, while maintaining gentle product handling at every step.

Across the range, all machines support the superior quality standards enabled by Citus Kalix molds and can be configured for quick changeovers between formats.

Flexible filling methods, seamless demolding

Citus Kalix machines are designed to accommodate a wide variety of filling processes. The same machine can handle direct pick-up from silicone molds, back filling, or top filling, offering flexibility to adapt to packaging types, formulations, and desired finishes.

Thanks to the silicone’s precision and release properties, even complex or fragile formulations retain their finish, texture, and dimensions throughout the demolding process. This is crucial when working with lipsticks that include engravings, special visual effects, or surface treatments.

Customization as a competitive advantage

Customization is a core feature of the Citus Kalix offering. The company provides a broad selection of standard molds for classic, mini, chubby, or stick lipsticks, with diameters from 6 to 22 mm and lengths from 16 to 51 mm. For clients looking to create signature products, fully tailored molds can be developed in collaboration with the Citus Kalix team.

A wide range of engraving options is available, from simple brand logos to full-surface designs with varying depths, creating a relief effect. These visual elements can be combined with selective rendering and texture finishes, including glossy, matte, velvety, or soft-touch surfaces, applied either to the entire bullet or specific areas.

This attention to detail has made Citus Kalix the trusted partner of many prestigious brands, like Givenchy, Guerlain, Lancôme, Armani, Prada, Yves Saint Laurent, Helena Rubinstein, Valentino, Céline, Gemey Maybelline, and Sephora.

All of this is made possible thanks to the expertise of the in-house mold engineers, who continue to refine both the material and the design process to meet evolving client expectations.

A reliable partner for luxury production

Over time, Citus Kalix has become more than a technology provider. It has established itself as a long-term partner to some of the most prestigious names in cosmetics. Brands choose Citus not only for its innovation, but for its ability to deliver consistent results, high-quality support, and full production flexibility.

The strength of this partnership lies in understanding both the technical demands of industrial production and the creative ambitions of luxury cosmetic lines. Every machine and mold is designed to uphold the brand promise and to support product differentiation in a highly competitive market.

Innovation you can see, precision you can trust

From patented technology to scalable production solutions, Citus Kalix continues to set the standard in lipstick molding with silicone. Every detail (material, machine, and method) is developed to ensure that brands can deliver outstanding products with confidence.

Ready to elevate your lipstick line?

Explore our full range of lipstick molding machines and customization services.

To get in touch:

- Christophe HERY (Area Sales Manager): christophe.hery@citus-kalix.fr

- Silvia TALLARIDA (Molds Specialist): silvia.tallarida@citus-kalix.fr

- Patrick ROSSI (Lipstick & Molds Process Supervisor): patrick.rossi@citus-kalix.fr

Let’s bring your next lipstick innovation to life.