Palletizing with robots and cobots

Citus Kalix offers advanced palletizing solutions tailored for diverse industries, ensuring efficient handling of closed boxes and packaged goods. With decades of expertise in production logistics, we design custom systems that optimize line automation and boost operational performance.

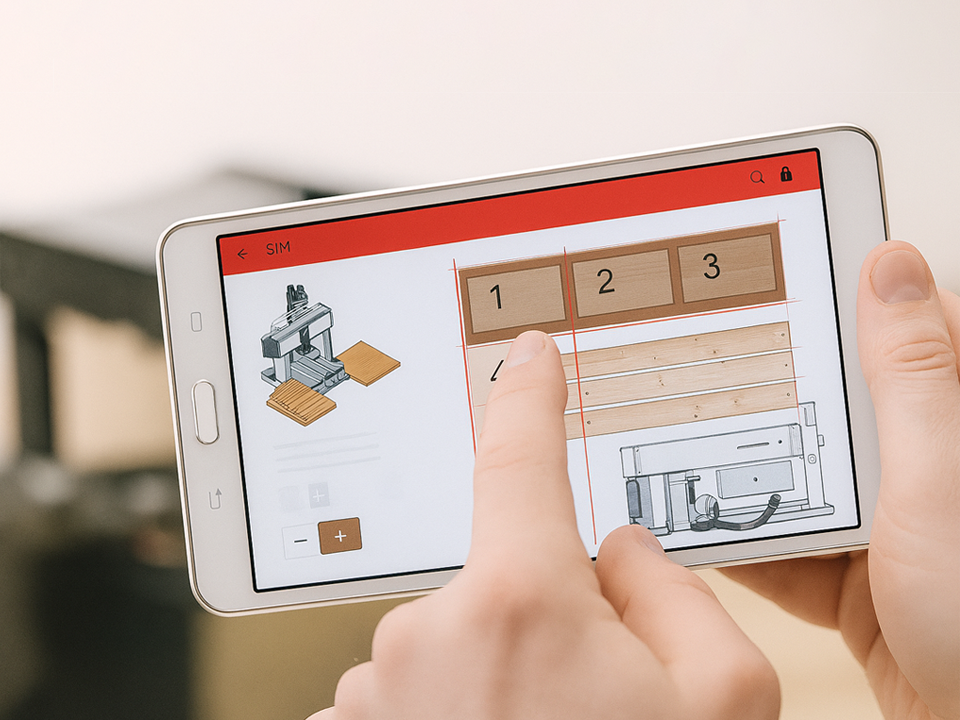

Our portfolio includes industrial palletizing systems and collaborative robots—such as the RC10 and RC20—developed in partnership with our Coesia sister company, FlexLink.

- Industrial Palletizers: Capable of handling payloads up to 15 kg at speeds of 12 cycles per minute, these solutions are ideal for high-volume operations.

- Collaborative Robots: Built to work safely alongside human operators, these robots manage payloads up to 12 kg at 8 boxes per minute, making them perfect for flexible and ergonomic workflows.

With a wide range of options and full integration within Citus Kalix, we deliver seamless, safe, and high-performance solutions for modern production environments.