The Future of Health & Beauty Tube Filling: Market & Technology Trends 2025–2030

How Citus Kalix supports the next generation of sustainable, high-performance tube packaging

Health & Beauty tube filling is entering a decisive modernization cycle. Sustainability regulations, refillable-first strategies, and increasingly complex formulations are reshaping equipment requirements. Between now and 2030, the leaders will be those who combine design-for-recyclability, ultra-fast changeovers, and digitally enabled quality—without compromising asepsis, dosing accuracy, or total cost of ownership.

Why Tube Filling Is Evolving

The European Packaging & Packaging Waste Regulation (PPWR) is moving sustainability from marketing claims to compliance. By 2030, packaging must meet recyclability performance grades and design-for-recycling criteria. This pushes brands toward mono-material tubes (PP/PE), higher PCR content, and simplified components. For machine builders, this means fillers, crimpers, and closing systems must adapt to lighter, more elastic laminates and single-resin sleeves—while maintaining seal integrity and throughput.

1. Demand-Side Drivers in Health & Beauty

a) Sustainability moves from claims to compliance

Mono-material tubes and PCR blends are no longer optional—they’re regulatory. Equipment must handle stiffness variability and thinner laminates without damaging aesthetics or compromising seal strength.

b) “Refill 2.0” and circularity

Refillable systems are scaling beyond prestige skincare into mass segments. This introduces cartridges, pouches, and refill tubes, increasing SKU diversity and requiring precision sealing that remains resealable and consumer-safe.

c) Formulation complexity & integrity

Active-rich formulas (vitamin C, retinoids, natural actives) demand oxygen and light protection. Airless tube architectures and improved headspace control are spreading, requiring clean dosing, accurate degassing, and validated seals.

d) Premiumization with agility

Health & Beauty growth remains strong globally. Brands want rapid varianting and seasonal drops without long changeovers—favoring servo-driven, recipe-based machines with tool-less adjustments and validated cleaning.

e) Microplastics and wastewater pressures

EU restrictions on microplastics and “polluter-pays” obligations increase scrutiny on formulas and downstream treatment—indirectly raising expectations for tighter filling, spill avoidance, and traceability.

2. Format & Material Trends in Tubes

- Mono-material PP/PE tubes and shoulders for recyclability; lighter laminates require gentler handling and optimized heat profiles.

- PCR content in tubes and caps, with stiffness variability demanding adaptive forming and inline quality checks.

- Airless tubes for preservative-light formulas; equipment needs precise piston/nozzle alignment and bubble control.

- Refill cartridges & pouches interfacing with primary tubes, driving smaller batches and higher cadence of changeovers.

3. Technology Shifts on the Machine Builder Side

a) Industry 4.0 as standard

Remote monitoring, digital twins for recipe setup, and predictive maintenance reduce ramp-up time and scrap. Expect integrated OEE dashboards and audit trails for premium and dermo brands.

b) Faster, cleaner changeovers

Modular dosing skids, quick-release product paths, and CIP/SIP-ready options enable rapid switches between gels, creams, clays, and scrubs while controlling cross-contamination.

c) Intelligent sealing & closing

Closed-loop control of temperature, pressure, and dwell time adapts to thin laminates and PCR variability. Vision systems verify crimp quality, cap presence/torque, and artwork alignment at line speed.

d) Traceable sustainability performance

Brands increasingly ask OEMs for validated recyclability-friendly settings and energy-use baselines per SKU to support ESG reporting tied to PPWR grades.

4. Operations & Investment Implications

Capex prioritization will favor fillers that maintain throughput with lightweight tubes—without raising scrap. ROI cases hinge on reduced changeover time (minutes, not hours), lower energy per unit, and fewer quality escapes.

Compliance readiness: lines that can document design-for-recycling choices and deliver electronic batch records will smooth PPWR and retailer audits.

Supply-chain resilience: qualification of multiple tube suppliers demands broader parameter windows; flexible, recipe-driven machines de-risk vendor variability.

5. Checklist for Future-Ready Tube Fillers

- Material-savvy mechanics: Auto-profiling heaters and adaptive torque control.

- Recipe intelligence & digital twins: Pre-validated parameter sets and simulation-based setup.

- High-integrity dosing: Air management, anti-drip cut-off, heated paths for high-viscosity pastes; optional nitrogen blanketing.

- Inline quality governance: Vision for fill height, seal geometry, artwork/cap verification; torque and seal data tied to e-records.

- Changeover excellence: Tool-less format parts, automated CIP/SIP; changeovers targeted in <15–20 minutes.

- Sustainability telemetry: Energy and scrap dashboards to support ESG and PPWR reporting.

6. Market Outlook

The tube filling machinery segment is set to grow at ~4% CAGR through the next decade, supported by automation demand across personal care and the U.S. market’s robust investment cycle. Expect outperformance for platforms that combine agility with validated sustainability and quality controls.

7. Strategic Takeaways

- Design for recyclability is now an equipment spec, not just a packaging brief.

- Engineer for volatility—more SKUs, smaller lots, frequent launches—via modular dosing and ultra-fast changeovers.

- Protect the formula, protect the brand: airless-ready dosing and rigorous inline QC are essential as actives intensify.

- Treat sustainability like a measured KPI: energy, scrap, and recyclability evidence must be visible at machine and line level.

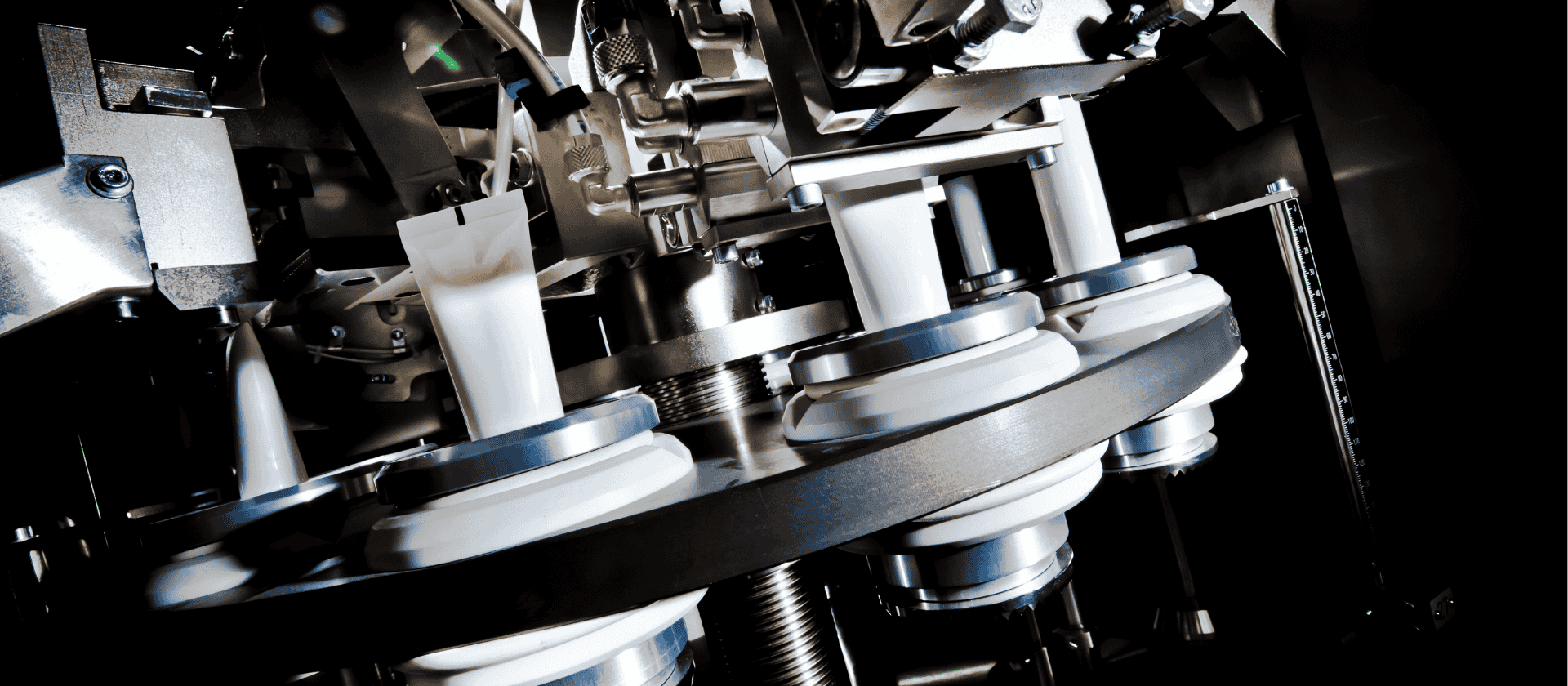

At Citus Kalix, we’ve anticipated these shifts. Our EVO line combines compact design, advanced automation, and rapid format changeovers with digital connectivity—helping beauty brands stay compliant, agile, and competitive in a fast-changing market.

→ Learn more about our tube filling solutions for health and beauty industry